Click to Chat

I'm online now.

Fhopepack Innovation

Case Study: Discover how Steel Shoppe, a leading steel processing unit in India, enhanced their operations with our custom-engineered Horizontal Slit Coil Packing Line, ensuring impeccable packaging and damage prevention.

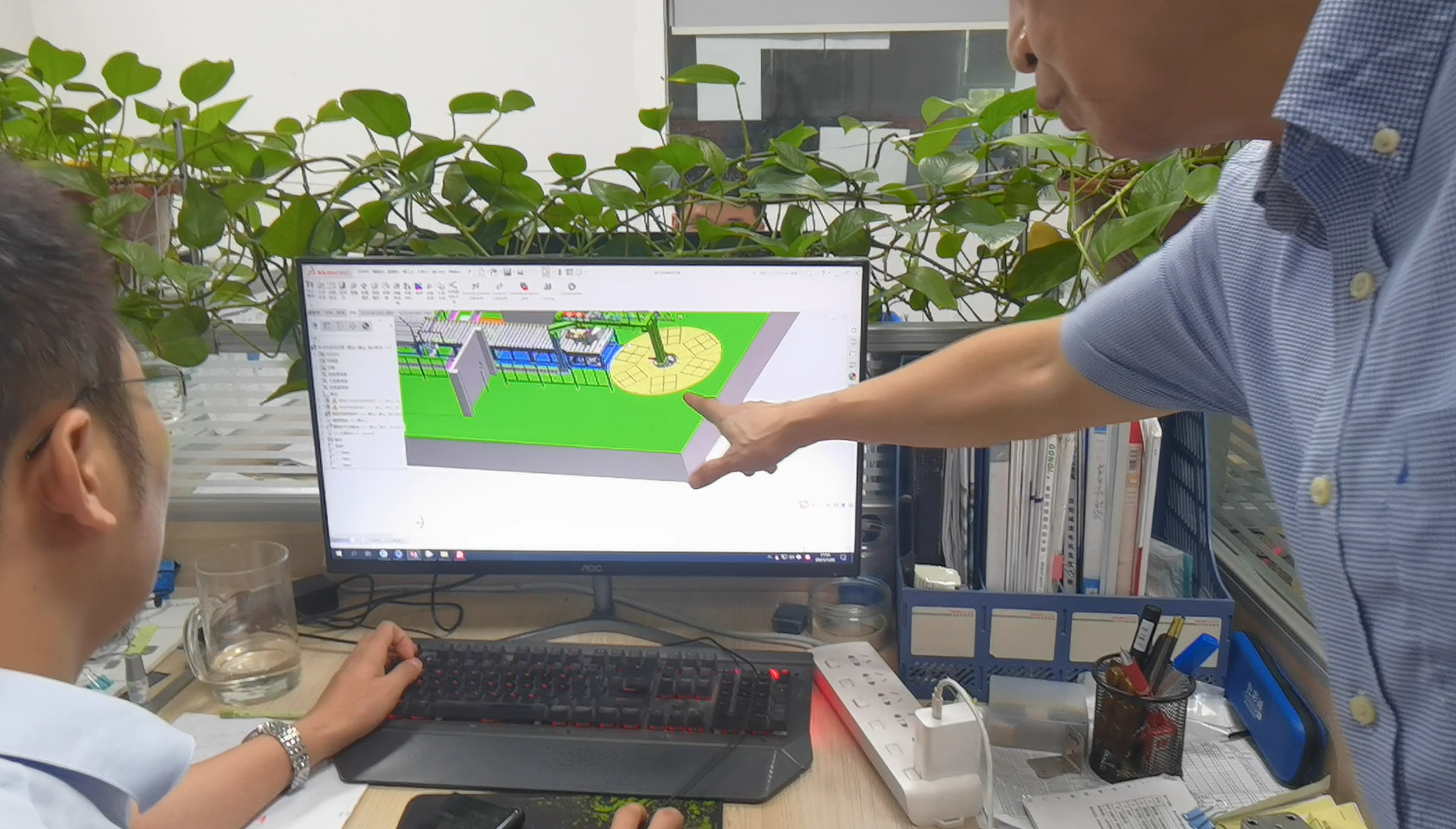

At FHOPEPACK, we pride ourselves on engineering robust and efficient packaging solutions for the demanding steel industry. This case study highlights our successful collaboration with Steel Shoppe (www.steelshoppe.in), a prominent steel processing unit in India, and how our bespoke slit coil packing line in India has transformed their packaging operations.

Steel Shoppe approached us with a clear objective: to implement a state-of-the-art packaging system capable of handling their valuable steel coils with precision, ensuring maximum protection during handling and transportation, and enhancing overall operational efficiency. Their commitment to delivering world-class products safely to their customers was paramount.

Understanding Steel Shoppe's specific requirements for handling steel coils with the following parameters:

We designed, fabricated, and commissioned a fully integrated Horizontal Coil Packing Line. This system incorporates several key automated modules to streamline their workflow:

For enhanced reliability and performance, the packing line utilizes premium components, including ABB/SIEMENS motors and SKF bearings. The hydraulic systems integral to modules like the down ender and lifting tables are engineered for durability and consistent power.

The implementation of our slit coil packing line has brought significant advantages to Steel Shoppe's operations:

We are delighted that Steel Shoppe has recognized the impact of our engineering. As they shared on their Instagram profile (@steelshoppe) on October 15, 2024:

"Our state of the art steel coil packing line guarantees impeccable packaging, extending shelf life and preventing damages during handling and transportation. With integrated weighment and unitizing facility, we deliver world-class products to our customers safely."

This statement from Steel Shoppe perfectly encapsulates the benefits our system was designed to deliver. Their focus on #SteelPackaging, #CoilPacking, #QualityPackaging, and #IndustrialSafety aligns directly with the capabilities of our machinery.

https://www.instagram.com/p/DBIqlKTzCR3/?utm_source=ig_web_copy_link

Our collaboration with Steel Shoppe is a prime example of how tailored automation solutions can elevate packaging standards and operational efficiency within the Indian steel industry. The successful deployment of this advanced slit coil packing line in India underscores our commitment to providing innovative and reliable machinery. We look forward to continuing our support for Steel Shoppe as they continue to deliver world-class products.

For more information on our custom-engineered coil packaging solutions, contact us today.

I'm online now.